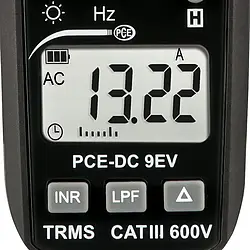

Automotive Tester PCE-DC 9EV

Views: 2218

$0.00

Small and compact design / Inrush current measurement / Ready for immediate use /

25 mm wide clamp opening / Optionally with ISO certification

Description

Small and compact design / Inrush current measurement / Ready for immediate use /

25 mm wide clamp opening / Optionally with ISO certification

Electromobility is playing an increasingly important role. It is therefore important to know the current flow in the lines. The wallbox of an electric vehicle can be monitored on the primary and secondary side with the automotive tester. The clamp meter can also be used in workshops to check electric vehicles. The starting current of the electric motors or the on-board current can be checked with the clamp meter.

In addition to the normal measuring mode, the automotive tester can also measure the inrush current. An inrush current measurement with the clamp meter is particularly necessary when starting up motors, such as ventilation systems, in order to rule out possible sources of error. In addition, the clamp meter has a low-pass filter function. This function can be used to determine currents in the low frequency range. Currents up to a frequency of 1 kHz are measured by the current clamp. The clamp meter is used, for example, to measure the current of low-midrange speakers (woofers).

Automotive tester for EV measurements – special features for electric and hybrid vehicles

In connection with the motor vehicles, the abbreviation EV stands for electric vehicle, which means for the vehicles with the electric drive. For the measurements of the electrics in conventional and electrically driven motor vehicles, a current clamp must be suitable for direct current measurements and it should be as compact and robust as possible because of the usually very limited space.

In contrast to the conventional vehicles with combustion engines, the vehicles with electric drives require much higher voltages and amperage for the powerful additional electrical consumers. For this reason, different voltage levels are used in the electric and hybrid vehicles, whereas in conventional diesel and petrol vehicles all consumers are usually supplied via the 12 volt (or 24 volt) battery. The current clamp for measurements on electric and hybrid vehicles should therefore ideally be able to precisely measure both the low current levels, e.g. of vehicle lighting, window regulators and cockpit displays, as well as the high current levels along the electric drive train.

Depending on the design of the automotive tester, the measurement results for direct current can be influenced to a greater or lesser extent by previous magnetisation and by other lines located close to the measuring point. It is advantageous if the current clamp automatically compensates for this by an offset check or can simply be set to zero before the actual DC measurement.

Since alternating current from the mains is primarily used to charge the batteries of the electric vehicles, converters are installed in the vehicles to convert alternating current into direct current. The required charging time depends on both the charging station and the equipment of the electric vehicle. In the case of the charging cables, as in the case of the other cables with connectors, the individual wires are not freely accessible. In order to be able to measure the individual wires with the current clamp during the charging process, special adapters are available. For example, there are measuring cases to which the charging cable is connected and which are connected to the charging station via a suitable connection cable. The automotive tester can then measure the alternating current on the individually tapped in the case connecting lines.

– Inductive current measurement

– Measuring range 0 … 1000 A AC/DC

– Backlight

– Small and compact design

– 25 mm / 0.98″ wide inner diameter

– Inrush current measurement

Specification

| Direct current | |

| Measuring range | 0 … 4 A DC |

| Resolution | 1 mA DC |

| Accuracy* | ±1.5 % of measured value ± 3 digits |

| Measuring range | 0 … 40 A DC |

| Resolution | 10 mA DC |

| Accuracy* | ±1.5 % of measured value ± 3 digits |

| Measuring range | 0 … 400 A DC |

| Resolution | 100 mA DC |

| Accuracy* | ±1.5 % of measured value ± 3 digits |

| Measuring range | 0 … 900 A DC |

| Resolution | 1 A DC |

| Accuracy* | ±1.5 % of measured value ± 3 digits |

| Measuring range | 900 … 1000 A DC |

| Resolution | 1 A DC |

| Accuracy* | ±2.0 % of measured value ± 3 digits |

| Overload protection 1000 A DC | |

| Alternating current | |

| Measuring range | 0 … 4 A AC |

| Resolution | 1 mA AC |

| Accuracy* | ±1.5 % of measured value ± 3 digits (50 / 60 Hz) |

| ±2.0 % of measured value ± 4 digits (40 … 400 Hz) | |

| Measuring range | 0 … 40 A AC |

| Resolution | 10 mA AC |

| Accuracy* | ±1.5 % of measured value ± 3 digits (50 / 60 Hz) |

| ±2.0 % of measured value ± 4 digits (40 … 400 Hz) | |

| Measuring range | 0 … 400 A AC |

| Resolution | 100 mA AC |

| Accuracy* | ±1.5 % of measured value ± 3 digits (50 / 60 Hz) |

| ±2.0 % of measured value ± 4 digits (40 … 400 Hz) | |

| Measuring range | 0 … 900 A AC |

| Resolution | 1 A AC |

| Accuracy* | ±1.5 % of measured value ± 3 digits (50 / 60 Hz) |

| ±2.0 % of measured value ± 4 digits (40 … 400 Hz) | |

| Measuring range | 900 … 1000 A DC |

| Resolution | 1 A AC |

| Accuracy* | ±2.0 % of measured value ± 3 digits (50 / 60 Hz) |

| ±2.5 % of measured value ± 4 digits (40 … 400 Hz) | |

| Overload protection 1000 A AC | |

| TrueRMS, crest factor up to 3% | |

| *With a crest factor of >2%, the accuracy increases by a further 2% | |

| Frequency | |

| Measuring range at 4 A AC | 1 … 10 Hz |

| Resolution | 0.1 Hz |

| Minimum current | 0.2 A AC |

| Accuracy | ±0.5 % of measured value % ± 2 digits |

| Measuring range at 4 A AC | 10 … 4 kHz |

| Resolution | 0.1/1 Hz |

| Minimum current | 0.08 A AC |

| Accuracy | ±0.5 % of measured value % ± 2 digits |

| Measuring range at 4 A AC | 4k … 40 kHz |

| Resolution | 1/10 Hz |

| Minimum current | 0.20 A AC |

| Accuracy | ±0.5 % of measured value % ± 2 digits |

| Measuring range at 40 A AC | 1 … 10 Hz |

| Resolution | 0.1 |

| Minimum current | 1.5 A AC |

| Accuracy | ±0.5 % of measured value % ± 2 digits |

| Measuring range at 40 A AC | 10 … 4 kHz |

| Resolution | 0.1/1 |

| Minimum current | 0.8 A AC |

| Accuracy | ±0.5 % of measured value % ± 2 digits |

| Measuring range at 400 A AC | 2 … 4 kHz |

| Resolution | 0.1/1 |

| Minimum current | 4 A AC |

| Accuracy | ±0.5 % of measured value % ± 2 digits |

| Measuring range at 1000 A AC | 1 … 4 kHz |

| Resolution | 0.1/1 |

| Minimum current | 40 A AC |

| Accuracy | ±0.5 % of measured value % ± 2 digits |

| Overload protection 1000 A AC | |

| Inrush current | |

| Measuring range | 4 A AC |

| Trigger current (threshold value) | 0.2 A AC |

| Measuring range | 40 A AC |

| Trigger current (threshold value) | 2 A AC |

| Measuring range | 400 A AC |

| Trigger current (threshold value) | 20 A AC |

| Measuring range | 1000 A AC |

| Trigger current (threshold value) | 200 A AC |

| Integration time 100 ms | |

| Overload protection 1000 A AC/DC | |

| Alternating current low-pass filter (LPF) | |

| Measuring range | 4 A AC |

| Resolution | 0.001 A AC |

| Accuracy | 3 % ±5 digits |

| Measuring range | 40 A AC |

| Resolution | 0.01 A AC |

| Accuracy | 3 % ±5 digits |

| Measuring range | 400 A AC |

| Resolution | 0.1 A AC |

| Accuracy | 3 % ±5 digits |

| Measuring range | 0 … 900 A AC |

| Resolution | 1 A AC |

| Accuracy | 3 % ±5 digits |

| Measuring range | 900 … 1000 A AC |

| Resolution | 1 A AC |

| Accuracy | 4 % ±5 digits |

| The low-pass filter refers to a frequency up to 1 kHz | |

| Further specifications | |

| All accuracies apply in an environment between 18 … 28 °C / 64 … 82 °F | |

| Clamp meter inner diameter | 25 mm / 0.98″ |

| Display | LC display |

| Measuring range selection | manual |

| Power supply | 2 x 1.5 V AAA batteries |

| Power consumption | 22 mA with background lighting switched off |

| Measuring rate | 3 Hz with numerical view |

| 30 Hz with bar graphs | |

| Operating conditions | -10 … 50 °C / 14 … 122 °F, <85 % RH, non-condensing |

| Storage conditions | -20 … + 60 °C / -4 … 140 °F, <75 % RH, non-condensing |

| Maximum altitude | 2000 m / 6561 ft |

| Dimensions | 152 mm x 66 mm x 36 mm / 5.98 x 2.59 x 1.41″ |

| Weight | 190 g / 6.7 oz (with batteries) |

Delivery Scope

1 x Transport bag

2 x 1.5 AAA batteries

1 x Instruction manual